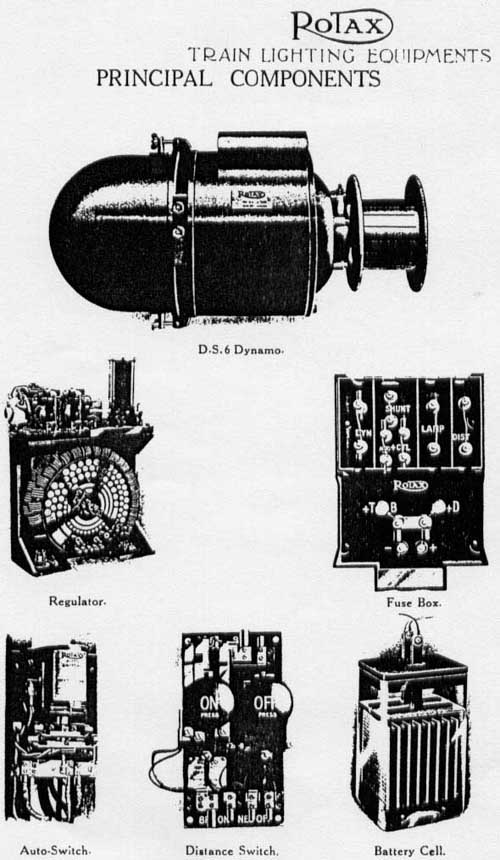

This system, which is the last word

in efficiency and reliability under continuous service conditions, is based upon the earlier standard " Leitner" system, with

such constructional modifications, simplifications and improvements as over a decade of practical experience by railway electrical

engineers of one of the largest railways in England — the Great Western Railway - has been able to effect.

The dynamo is four pole and of the now well-known and thoroughly tried variable speed auxiliary brush type actuated by any convenient

drive from a carriage axle, such as a non-slipping belt. It is this type of dynamo that in its miniature sizes is used in enormous

numbers throughout the world for motor car lighting and the like, and whilst unsurpassed for electrical efficiency and absolute

reliability, its mechanical construction for railway train lighting is of great robustness and simplicity in accordance with actual

railway experience gained. Electrically connected to a battery of accumulators, its voltage follows the state of the battery and is

practically constant through the whole speed range by its inherent regulating property. These dynamos are made in various sizes of all

outputs required in practice, and each size or type is completely interchangeable as to parts, as the manufacture is of the most

up-to-date and best conceivable practice and completely standardised.

According to the direction of rotation required the "rocker" carrying the brushes revolves through the requisite angle with

absolute certainty with no mechanical engagement of any sort, the friction of the brushes being sufficient to effect the movement.

One dynamo may be used for each individual railway coach or for several coaches, or one dynamo for a whole set or block train, depending

upon traffic requirements and conditions. Climatic variations and conditions do not affect any of the apparatus. The system in its best

or most effective form employs only a single battery of 12 accumulator cells per equipment Lead-Lead Sulphuric Acid Plante type; an "

Auto-Switch", that is to say, a simple and robust automatic cut-in and cut-out switch is electrically connected between the dynamo

and this battery. A further piece of apparatus, which may be operated either by hand or electrically from the guard's van, is

a "Distance Switch" which turns on or off the lights in each compartment of the whole train.

Finally there is an automatic regulator which regulates the voltage of the lamps independently of the rise and fall of battery voltage

and also controls the charging rate of the dynamo, reducing the latter to a negligible quantity when the battery is fully charged.

In first cost this system, owing to its simplicity and the unsurpassed manufacturing equipment of the manufacturers, is moderate

considering the work it performs and the high grade workmanship of the component apparatus. As regards cheap operating costs and low

maintenance charges, including upkeep of batteries and lamps, there is nothing approaching this system on the market. We can guarantee

to suit all the individual requirements of any particular service of which the special conditions are communicated to us.

Manufacture

of the apparatus is carried out under the supervision of a specialized staff of expert engineers with many years' experience of

Train Lighting apparatus.

The Leitner Variable Speed Dynamo

Technically Described

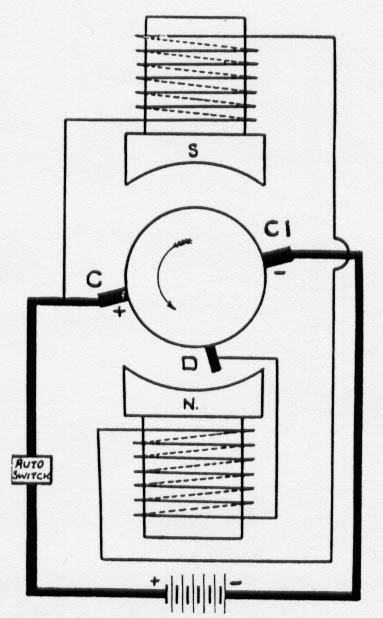

The diagram shows

a bi-polar machine in which the principle is applied in its simplest form, although in practice four pole machines are employed. It

will be seen that there are three brushes : two main and one subsidiary. The dynamo is shunt wound. The action of the subsidiary brush

in automatic regulation may be explained as follows :—

The diagram shows

a bi-polar machine in which the principle is applied in its simplest form, although in practice four pole machines are employed. It

will be seen that there are three brushes : two main and one subsidiary. The dynamo is shunt wound. The action of the subsidiary brush

in automatic regulation may be explained as follows :—

Let the direction of rotation be "counter clockwise" and leave out of consideration the theory of generation of current at

the main brushes C and C1. There will be at starting a potential difference between the subsidiary brush D and main brush C. This

difference of potential is proportional to the angle between C and D.

As the current flowing out of the armature at the main brushes C and C1 increases, the armature flux increasingly distorts the field

flux in the direction of rotation, and in consequence the voltage between the subsidiary brush D and main brush C is gradually

reduced so that the field is weakened proportionally to the increase of speed and load and keeps the voltage on the battery practically

constant, irrespective of speed variations.

BOTH theoretically and by long practical working tests, the "Leitner" system has shown its superiority to all its competitors.

The fact that the subsidiary brush ("Leitner") dynamo, which is merely a miniature train lighting dynamo, is practically

exclusively used under various names all over the world for automobile lighting and aviation purposes, speaks for itself.

Train lighting systems that depend upon mechanical slip are the most wasteful of all; the energy consumed and wasted in harmful

directions is prodigious and costly. The extensive adoption of such apparatus is merely a strong proof of the superiority of even

the least efficient electric lighting system versus gas lighting. Systems that mechanically connect the dynamo to the accumulator

battery are under the grave disadvantage of taking no cognizance of electrical conditions, so that a burnt-out or defective armature

may cause further harm by being put in circuit, besides the liability of mechanical cut-in and cut-out devices getting out of order

and burning their contacts. In the "Leitner" system, armatures cannot burn out to commence with, and connection or

disconnection between dynamo and battery depends entirely on correct electrical conditions prevailing.

Systems depending upon any electro-mechanical device for regulating the dynamo output in regard to of rotation, merely substitute an

expensive, complicated and sluggish apparatus for the "Leitner" third brush. For the instantaneous and reliable regulation of

the latter, something that may and does get out of order is employed, and if it should not respond quickly enough as in the case of

inadvertently skidding the railway carriage wheels at high speeds and being released again — the whole system may be seriously

affected and thrown out of action.

Constant potential systems impose heavy loads on the generator unless the potential is taken far lower than necessary or desirable

for maintaining the battery in good condition. They do not work well in parallel, dynamo output is dependent upon battery resistance

i.e., size or capacity — and there is the constant danger of burnt-out armatures.

Systems with short circuited brushes entail heavy initial starting effort and, or, introduce also of necessity a variety of subsidiary

undesirable apparatus and complications. Such dynamos are bound to be larger and less efficient than normal machines.

Whether single

or double batteries are used, nothing simpler or more reliable than the " Leitner" variable speed dynamo, with accessory

apparatus as manufactured in its latest form by Messrs. Rotax (Motor Accessories) Ltd., is or can be made with any even approximative

degree of efficiency.

Systems with double batteries in which one battery has to furnish the dynamo field current before it is capable of functioning, have

obviously the initial grave defect that if both batteries should be exhausted, which may readily happen, the dynamo and therefore the

whole system will not function at all.

The "Leitner" (1921) system, made exclusively in our Works at Willesden Junction, London and Taunton, is the only known

Train Lighting Equipment which completely satisfies all traffic conditions on any railway, including the automatic recharge and

reclaiming of accumulator batteries discharged to zero and sulphated.